TOPページの写真で弾いているチェロは1900年にチェコで作成されたもので、

購入した時にトゥルトゥリエモデルのエンドピンを取り寄せてもらって使ってます。

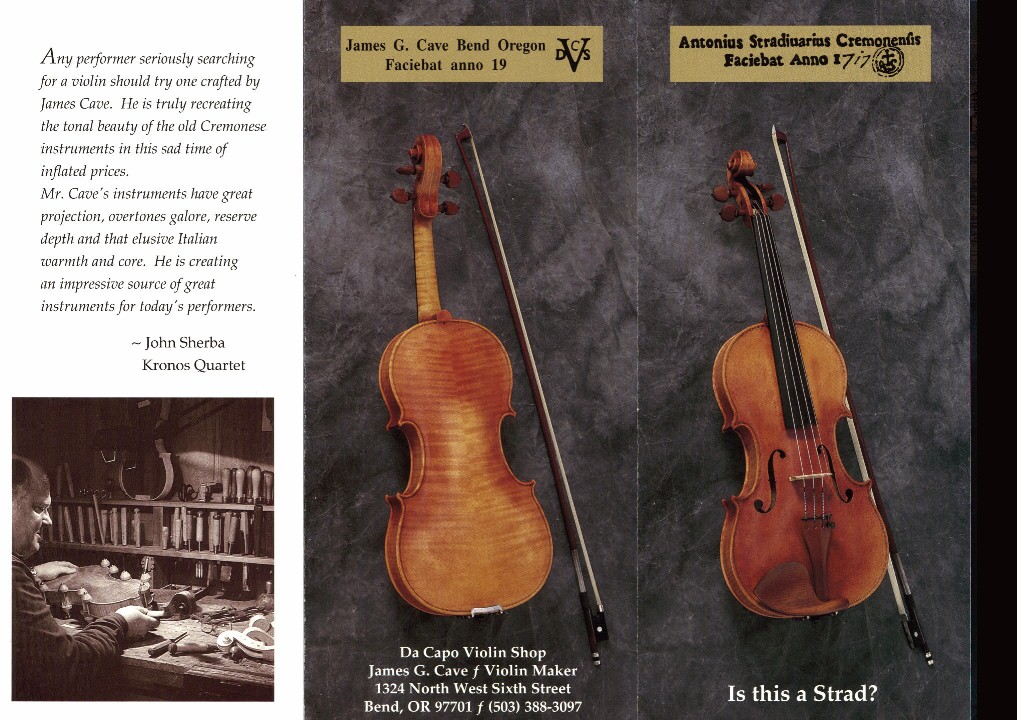

現在主に使っている(ほとんど弾いてませんが)チェロは あるカリフォルニア在住の

プロヴィオラ奏者の使っている楽器の音がよかったので、その人の薦めで購入しました。

1982年に James Cave氏(現在サンフランシスコ近郊に在住)が作成したもので、

名器モンタニャと弾き比べても負けない深い響きと大きな音が特徴です。

new address: 16137 Via Del Robles, San Lorenzo, CA 94580, phone 510-481-2368,

mailto: jamescave@earthlink.net or lenorevla@earthlink.net

The latest news article from the Hayward Daily Review (Sunday, February 20, 2000):

Perfect body and voice work of local craftsmanBy Jeanie R. Wakeland

STAFF WRITER

HAYWARD -- With a turn of his chisel, James Cave can create a body curvier than Cindy Crawford's and a voice sweeter than God's favorite angel.

With $300 worth of European maple and a year's worth of work, Cave crafts violins, violas and cellos in his Hayward workshop.

And when he's completed his work, he hands them over to his wife, professional violinist Lenore Gilbert, for a test run.

Music is the life and work of Cave and Gilbert. Twenty-three years ago, Cave, a San Lorenzo resident, left a full-time secure job with the Veteran's Administration to devote his time to instrument-making and repair. Lenore, a violinist with the Modesto, Napa, California and Santa Rosa symphony orchestras, came into his life as a customer at his San Francisco shop. Like the bass and treble lines of a Bach sonata, they complement each other.

Supportive wife

Even if she hadn't married him, said Gilbert, she'd want to play his violins.

"They're very melodious and have a quick response," she said. "The tone is even from top to bottom. They're superior to the antique instruments I've used."

Cave said he has found a way to make his new instruments sound as good as a high-quality old instrument. His clients seem to agree. He has a three-year waiting list for his concert-quality and soloist instruments, which can cost from $8,000 for a professional quality violin to $16,000 for a soloist quality instrument.

What's his secret?

"I can't tell you that," he said, smiling.

Handmade

He will say the instruments are all carved by hand -- a prodigious job of gentle and exacting work because he shaves the inch-thick wood slabs into slender fronts and backs about 2.4 mm to 2.8 mm deep.

He uses an animal-hide-based glue to attach the front, back, sides and neck. Newfangled super glues won't work, he said.

"One can separate the joints if you need to work on the instrument in the future," he said. "That's impossible with new glues."

The finger boards, where the performer presses the strings, are made of ebony.

"It's so heavy a wood that it sinks in water. It plays like iron," he said.

That's necessary for performers who press hard on the strings or play a lot, he said.

"I've had to repair finger boards with lots of ripples," he said. "That affects the sound because the strings will buzz. You have to plane it."

Perhaps the most delicate work in making a violin is putting in the purfling, the thin wood inlay that follows the curvy outline of the instrument front.

The inlay, less than 1 mm thick, is delicately inserted into a groove with a tiny pick.Layers of handmade varnish

"I can do it for about 45 minutes, and then I have to go outside for a breather," he said.

His closest-held secret is the contents of his varnish covering the wood. Like the great instrument makers Stradivarius and Guarneri, the layers of handmade varnish seem to make all the difference in creating a great tone from the thin maple boxes. The varnish is applied in thin layers over six months.

"I've spent a lot of time developing it," he said. "What I look for is real clarity."

Unlike most instrument makers, Cave didn't learn this skill at the bench of a mentor, but from a book and from trial and error.Enchanted by Beethoven

He didn't even begin to appreciate classical music until his mid-20s, he said.

One day, he heard on the radio a recording of Jascha Heifetz playing Beethoven's Violin Concerto. It enchanted him, and he decided to take violin lessons.

"Pretty soon I was more advanced than my teacher, who was not very good," he said.

But, what really fascinated him was the instrument.

"How could this box of wood make this incredible sound?" he said.

He found a book at Berkeley's public library on how to build instruments.

"I'd never done any woodworking, not even a brick and board bookcase," he said.

He completed his first violin and took it to a violin shop in San Francisco. The shop owner wasn't impressed with the instrument, but he took enough interest in Cave to advise him about tools and to photocopy other books. He kept building instruments, one after another, for 10 years, until in 1977 he felt he was ready to make a living at it.San Francisco Conservatory

Now, he's sharing what he knows with another former customer, Oliver-Nghia K. Truong. Truong used to stop at Cave's shop when he was a student at the San Francisco Conservatory of Music. In the 17 years he's known Cave, he's earned a degree in music performance at the University of California at Los Angeles and is completing a master's degree in business. He's also become Cave's business partner and apprentice.

"I slowly realized the instruments I've been getting (from him) these days are pretty dramatic. The quality is high," said Truong. "I'm still in learning process. I'm not a maker at this point, but I'm learning from him."

Truong has played his Cave violin in chamber music groups in Southern California.

"The (other players) were very impressed that a brand new can sound just beautiful," he said. "There's a distinct quality to it. If you play on one of his instruments, it gives musicians the sound he or she wants to produce."No regrets about leaving job

At this point in his life, Cave said he had no regrets about leaving his secure federal job.

"Nothing is as wonderful as sitting in the audience and hearing my instruments on the stage," he said. "I feel almost separate from it, as if I didn't really create this. It's a gift, and I'm just a custodian of it."